In the fast-paced world of textile manufacturing, every second counts. To ensure maximum efficiency and productivity, industries are constantly on the lookout for innovative technologies that can enhance their operations. One such technology that has revolutionized the weaving process is the weft accumulator.

What is a Weft Accumulator?

A weft accumulator is a device used in textile weaving to store, measure, and distribute yarn during the weaving process. Its main purpose is to enable uninterrupted weaving by continuously supplying weft yarn to the loom, eliminating downtime caused by yarn exhaustion or tension problems.

How Does a Weft Accumulator Work?

The weft accumulator primarily consists of a large cylindrical-shaped frame with grooves or notches. The yarn is wound onto a tube or spool, which is then inserted into the grooves. As the weaving process begins, the weft accumulator rotates at a speed synchronized with the loom. The grooves release the yarn at a calculated rate, ensuring a constant and evenly distributed yarn supply to the weaving machine.

Benefits of Weft Accumulators

1. Improved Productivity: By eliminating the need to frequently stop the weaving process to change weft packages, weft accumulators significantly increase productivity and minimize downtime. This improvement allows manufacturers to produce more fabric within a given timeframe and meet customer demands more efficiently.

2. Enhanced Yarn Utilization: With a weft accumulator, the yarn is replenished to the loom in a controlled manner, preventing the wasting or misalignment of yarn. This efficient yarn utilization translates to cost savings and a reduction in material waste.

3. Maintained Quality: Weft accumulators ensure consistent weft tension throughout the weaving process, thereby promoting uniform fabric quality. By preventing tension variations and yarn damage, these devices contribute to the production of high-quality textiles.

4. Versatility: Weft accumulators are adaptable to various weaving machines and can be easily integrated into existing production lines without significant modifications. This versatility allows manufacturers to upgrade their weaving machinery without major disruptions, thus enhancing overall productivity.

5. Scalability: Weft accumulators are designed to handle a wide range of yarn types, sizes, and materials. Its adaptability grants manufacturers the flexibility to work with different yarns without compromising productivity or quality, as well as the opportunity to explore new textile product variations.

The new system inherited the superior performance of the previous generation, co...

Sanhe SHJ-P series design adopts pattern prediction and FOC drive technology, wh...

SHJ-A / B series, Sanhe, based on many years of experience in the production of ...

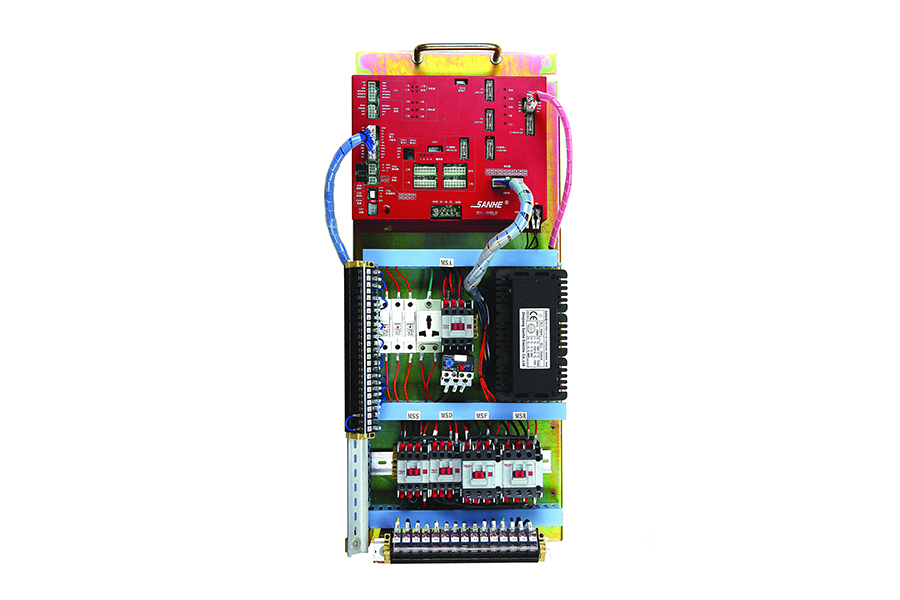

Through five years of exploration and research, Sanhe launched integrated contro...